by Detroit Chassis | Jun 6, 2016 | Uncategorized

This is how we do it!

Detroit Chassis Leaders and Associates passionately support the community in many ways, including active participation on boards at the governance level, and by contributing valuable time and resources to achieve stated goals that promote youth and education.

Each Associate is encouraged to contribute 24 hours annually towards community related activities of their choice.

Along with the many programs we collectively supported this year, we are showcasing:

The National Association of Black Suppliers Scholarship Fund

We make dreams happen by investing in the educational journeys of high potential, high achieving African American

students through mentorship, support and networking with our students throughout their education and beyond. We involve our past graduates in the journeys of current students and we invite our graduates to work to continue our mission. Recently, 14 students were selected to receive college scholarships and they were recognized at the Annual Awards Ceremony at the Henry Hotel in Dearborn, MI. The organization recognized its founders during the awards ceremony at which Dave Bing, Founder and Chairman, Bing Youth Institute was the keynote speaker and awardee. www.nabssf.org.

Concerned Christian Men (Chicago, IL)

We are an organization of Christian Men that strives to serve as “Fathers to the Fatherless” building servant leaders who are responsible to their communities and families through Modeling, Mentoring, Mastering, Motivating, and creating Momentum for achievement for more than 10 years. Sponsorships are still available for this year’s Annual Awards Program scheduled for June 25, 2016 at Apostolic Church of God Chicago, IL. For more information see www.concernedchristianmen.org.

Junior Achievement of SE Michigan Junior Achievement of Southeastern Michigan impacted 43,000 students with the help of 2,203 volunteers this past school year. Our volunteer-delivered, kindergarden-12th grade programs

foster work-readiness, entrepreneurship and financial literacy skills, and use experiential learning to inspire students to dream big and reach their potential. JA students develop the skills they need to experience the realities and opportunities of work and entrepreneurship in the 21st-century global marketplace with the help of business and community volunteers. www.juniorachievement.org/web/ja-sem

Business Applications in Manufacturing Management (Detroit, MI)

Detroit Chassis provides students a 10-week professional development program with hands on experience in the “real world of work” focusing on high performance and teamwork from an entrepreneurial perspective. We share our culture and values with students and task them to create a personal mission statement, develop long and short-term goals, work effectively to achieve them and receive rigorous weekly performance feedback. This program is conducted concurrently with the school year and students receive credit towards completing high school graduation requirements.

Educate Create Innovate Entrepreneur Relationships (Gary, IN)

The ECIER Foundation was created to educate, empower and equip our youth to realize their potential and achieve their dreams. Students are required to attend innovative entrepreneurial workshops focused on developing their academic, creative and leadership skills. Students design and implement an innovative project and perform community service. This April students along with members of the ECIER BOD spent the day at Detroit Chassis touring the facility, observing the production build process, hearing the success story of our owners and participating in communication / team building activities. www.ecier.org

Gary Alumni Pathway to Students (Gary, IN)

The Gary Alumni Pathway to Students is a group of alumni from Gary Indiana’s Westside High School that work to bridge the gaps between school faculty and students. They collaborate with school administration, faculty and students to develop and implement programs that encourage academic achievement, life skills and career exploration. Though this group of professionals is located across the country, they remain committed to utilizing their gifts and talents to supporting the Gary, Indiana community.

City of Detroit Grow Detroit Youth Talent

Detroit Chassis in conjunction with the City of Detroit is participating in the Grow Detroit Youth Talent program along with the many Detroit area businesses committed to assisting the Mayor in securing summer employment for 5,000 Detroit students between the ages of 14 and 21. Detroit Chassis has selected students who previously completed the internship program to work in the Engineering, Materials and Information Technology departments for a 6-week period.

Detroit Chassis remains very much committed to win/win outcomes through teamwork, respect through diversity and community and to making a positive impact in our community!

by Detroit Chassis | May 20, 2016 | Uncategorized

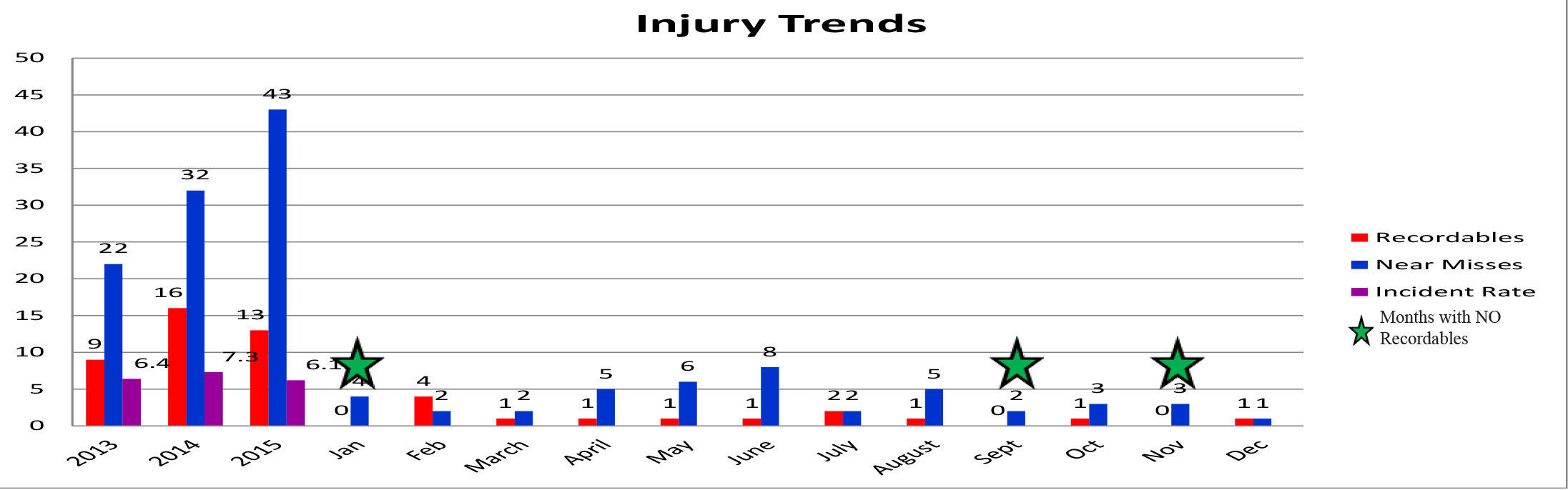

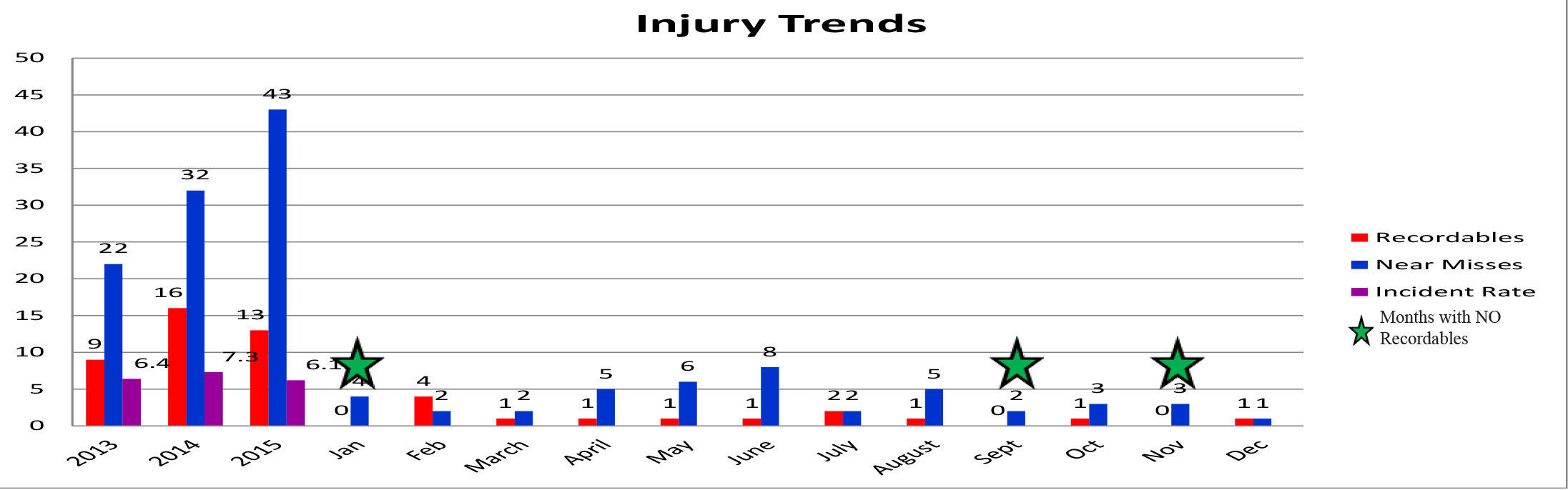

Detroit Chassis leaders participated in a recent Balance Scorecard Meeting that reviewed pertinent metrics that show how well departments and projects are performing. Metrics show the organization is performing well and continuous improvement activities will sustain this outstanding level of performance.

SAFETY has surpassed 100 days without incurring a recordable injury. This is the kind of SAFETY performance we like to deliver and we are glad that the organization has stabilized in this area.

There are several factors that can affect an organization’s SAFETY record including training, new hires, absences, etc. To celebrate this achievement everyone enjoyed free lunch Thursday, May 19, 2016. Great Job!

Our ISO surveillance audit was completed without any non-conformances and received complimentary remarks from the auditor in several areas pertaining to production and customer service processes.

The results reflected in the audit report confirm that the Detroit Chassis quality management system was developed, documented, applied, is active and constantly renewed, and consistent with international standard ISO 9001:2008 requirements.

DCP is measured monthly within the FORD Inventory Monitoring and Production Inventory System. This measurement tool called SNURK monitors our bailment inventory and ensures DCP is functioning efficiently while reporting on the status of inventory.

DCP’s SNURK report is ALL GREEN. The Materials team has done a wonderful job staying on top of reporting our performance in this area that has been strongly trending positively since December 2015.

Our Materials team works with Ford MP&L to provide “JOY” to Ford Motor Company. Great Job!

Key representatives from Jordan Auto stopped by and were interested in examining 2017MY PP units. Quality and Customer Service joined forces and cleared schedules to accommodate this request. Marvin Dawson, Fixed Operations Manager and Tony Bucci, Parts Manager from Jordan Auto were pleased with the organization’s responsiveness.

Tony sent the following message in a follow-up communication.

“I can’t thank you enough for all of your help. Also I still don’t quite have the right words but I am going to try to sum up the great experience we had up at the plant with you. Not only were we made to feel welcome on such a short notice, but the atmosphere and culture of everyone in the plant is amazing. Every time we wanted to see how something was assembled there was never a hesitation to take the time, and even though it was a disruption on production it was done with a smile. Watching the interaction with everyone was amazing. You have quite the family atmosphere and to say the least I am impressed as that is the culture we strive for here at Jordan. Again, thank you both and the many people whose way we were in for all you do day in and day out.” – Tony Bucci, Jordan Auto

Thank you for your feedback Tony!

Speaking of feedback it is time to launch the Detroit Chassis 2016 Customer Satisfaction survey for F53 Motor Home and F59 Commercial Truck manufacturers.

Manufacturers will receive notification to respond to the survey by the end of this month. All responses are expected by Friday, June 10, 2016.

We endeavor to provide sustained “JOY” to all of our customers!

by Detroit Chassis | Feb 26, 2016 | Uncategorized

WE VALUE CUSTOMER FEEDBACK

Paul Levandowski, APQP Manager and MeShawne Johnson, Change Control Coordinator were nominated by the FORD Motor Company Commercial Vehicle Management team for recognition at the Friday, February 12th, 2016 Appreciation Breakfast.

Each month FORD Vehicle Special Order (VSO) invites individuals to a coffee/juice and bagel breakfast to show how much they appreciate the support received. Often requests are made and speedy responses are necessary on projects that usually require extraordinary effort to accomplish.

Paul and MeShawne have been instrumental in responding to the needs of the customer creating joy!

“Congratulations to the team and to both of you on an exceptional job managing through the recent engine and related powertrain component changes. We are all pleased that the customer is recognizing your effort and success with this.”

“Please continue to share this appreciation, as you have, with your colleagues who supported. Well done! — Michael Boyle, General Manager

Brent Stowell, Materials Manager reported that Detroit Chassis obtained GREEN status in all categories on the SNURK report for the Month of December 2015. This progress was shared with the executive team and managers in the last Balanced Scorecard Meeting. This level of performance is appreciated and well received by FORD Motor

Company’s MP&L group.

On a monthly basis, DCP is measured within the FORD Inventory Monitoring and Production Inventory System. This measurement tool monitors the bailment inventory and ensures DCP is functioning efficiently while reporting on the status of inventory. It feeds this information into the daily SNURK report.

Congratulations to the team and to Chuck Watts, Materials, Inventory and Cycle Count Manager, and Kevin Greer, Materials Analyst and Coordinator for outstanding delivery and performance in this area of expertise. Thank you for meeting expectations for Customer Joy, Effective Communication, Commitment, Integrity, SOUL and Respect!

FINAL LINE

Walking down Final Line looks so nice and orderly. Demetrius Gunn, Team Leader wanted to clean and organize this area by removing extra boxes that created clutter and posed trip hazards.

A rack was installed for Park Brake Cables. The cables are now placed in the proper slot, which is colored-coded and labeled. Not only did we reduce the foot print required for six different part numbers we also created an area that is robustly organized and serves as a visual management for material handlers.

We all want a clean and orderly house, the only way to make this happen – is for all of us to pitch in and do our part.

We spend an average of 8.5 to 10 hours per day at work with our DCP family and we are taking 5”S” to the next level by keeping our DCP house clean and orderly. Thanks to the team for all of your efforts.

5”S”

Pauline Player, Production Lead has implemented another layer to the 5”S” Housekeeping Auditing Process.

Team leaders are now responsible for auditing their areas. Everything not required in an area will be tagged “Red” and removed. Items will be taken to a designated area and reviewed.

TEAM LEADER BOARDS

Now you can see the current status of any DCP Operations Team by taking a look at the Blue Board posted in that area. Thanks to the team for making this possible.

Every team board has current and real time information about SAFETY, Injury Trends, Locations, Near Misses, and Corrective Actions. The boards also display current Quality information, Scrap, Scrap Cost, Production, Hours Per Unit, etc.

Team leaders own their areas and along with ownership comes an understanding of all of the activities, challenges and progress in these areas.

Stop by and have a conversation with a team leader. They will be eager to explain their current status to you.

![Safety Update]()

by Detroit Chassis | Jan 29, 2016 | Uncategorized

Good SAFETY performance is important and contributes to the bottom line.

Detroit Chassis is showing improvements in SAFETY and the team is focusing on making the SAFETY Program more robust. The Incident Rate for 2015 is 6.19 just above the industry average. Our goal is to achieve World Champion performance so clearly we have work to do to realize better results in SAFETY. Everyone on board is excited about working together to improve our SAFETY performance.

Near miss and Unsafe Conditions are also tracked, discussed at length in various meetings and precautionary measures are implemented to eliminate the cause and keep the incident from reoccurring.

You can help with this process. The first step is to recognize a hazard in the workplace, for example “A puddle of fluid on the floor, seems simple but what you do with the puddle is a different story. Do you walk through the puddle, assuming it is only water? What about the oil or grease on the bottom of your shoe? When you introduce water, you create a potential slip issue. A slip issue that could have been prevented if:

- the puddle had been reported to Facilities/Supervisor

- the puddle had been cleaned up or the area blocked off until additional resources could help

- travelers walked around the puddle

Some health and safety hazards are not always obvious. Hazard recognition also includes:

- Identify potential hazards in your work area

- Identify the adverse effects that may be associated with the hazard

- Determining whether there is a possibility of people being exposed or affected by the hazard

If a potential hazard is recognized using these three steps, the hazard must then be assessed. Hazard assessment is a process of evaluating an identified workplace hazard. The assessment covers equipment, process and work procedures. An assessment considers which Associates, if any, are exposed – or likely to be exposed – to an identified

hazard and for how long.

- Lacking Machine guards

- Biological or Chemical hazards

- Ergonomic hazards

- Excessive noise, vibration, energy, weather, heat, cold, electricity, radiation and pressure

If you see or are experiencing any of these hazards or have any additional concerns, please contact your Department leaders for help.

by Detroit Chassis | Dec 30, 2015 | Uncategorized

This year’s holiday celebration was held at the plant Friday, December 18, 2015 at the conclusion of the production day.

Many thanks to company owners Michael and Carlton Guthrie for making this celebration possible, to suppliers Curtis Evans, Curtis Industrial Services; Walter Rosati, Sigmapac and Stacy Meagher, Creative Marketing Solutions for donating gifts and prizes for the free raffle give-away. Michael and Carlton Guthrie also contributed 2 Detroit Chassis black fleece embroidered jackets. Associates had 38 chances to win great prizes.

A hearty thank you is also extended to Jackson’s Five Star Catering for providing the tasty meal of Fried Cat Fish, Chicken (baked and fried), Macaroni & Cheese, Mashed Potatoes, Greens, Green Beans, Fresh Rolls, and Tossed Salad. Desserts were provided by Detroit Chassis.

The 2015 Christmas planning committee led by Human Capital did a wonderful job preparing for the event. This year’s celebration was packed with anticipation and excitement. Thirty-eight Associates won prizes including tickets to the Janet Jackson concert and gift cards from Massage Envy, Citgo/Shell Gas, Wal-Mart, Meijer’s, Lowe’s, Bed, Bath and Beyond and tickets to Detroit Pistons and Red Wings games.

Merry Christmas and Happy Holidays!

See you in 2016!

Linda J. Ratliff-Watkins

Contact: Linda Ratliff, 313-571-2100 x 506, lratliff@detroitchassis.com

Recent Comments